While research and development activities are an important necessity for increasing efficiency and profitability for businesses, they are also the key to economic and social welfare for country governments. States grow with their businesses that produce high value-added products and can play an active role in global decisions. With this awareness, public authorities have been offering various incentives for many years to increase research and development investments for businesses to focus on new or significantly improved product, service and process development activities.

In Turkey, the concepts of R&D and Design Center were defined with the "Law on Supporting Research, Development and Design Activities" No. 5746, published in 2008. In line with the law, it is aimed to combine public supports for R&D activities at a single point, to present incentives in a more systematic and traceable manner and to measure the outputs. Dikkan R&D Center adventure, which has been carrying out R&D activities and processes since its establishment, started in 2017 with the approval of the ministry as the first R&D Center in the valve industry.

Dikkan offers acceleration of innovation and R&D for value-added, difference-making, sustainable technologies in the business line in which it operates. Therefore, the R&D Center is included in Dikkan's know-how as a business unit, beyond just a research and development center. Ideas, studies and developments are implemented as new products and solutions with Dikkan experience.

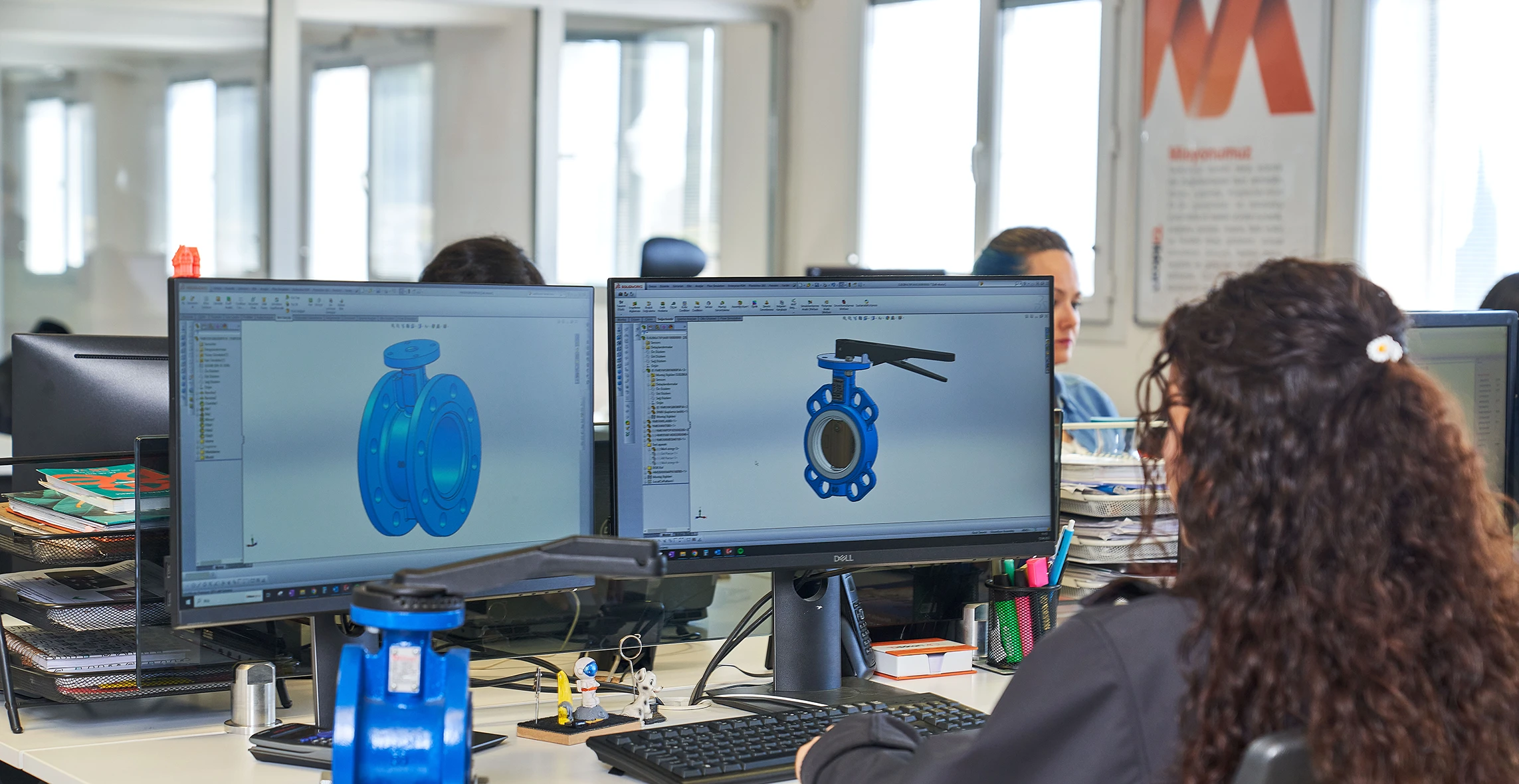

Dikkan R&D Center has a multidisciplinary staff consisting of graduates of Machinery, Metallurgy and Materials, Computers, Industrial Designers and Basic Sciences. It continues its work with TÜBİTAK and KOSGEB projects, patent and utility model applications, and design registrations, which have been completed, ongoing and in the preparation phase since the first day of its establishment. The outputs obtained within the scope of the developed projects are presented as papers or posters at relevant symposiums and congresses or sent to journals as scientific publications in order to contribute to the literature and lead the industry.

The R&D Center management, which also attaches importance to university-industry cooperation, formalizes the studies by creating protocols with universities, especially in the Aegean Region. Protocols have been signed with Yaşar University, Dokuz Eylül University, İzmir Institute of Technology, Manisa Celal Bayar University, Ege University, Concept Vocational School, and negotiations are continuing with other universities where studies are ongoing. Within the scope of the signed protocols, university-industry activities such as supporting the graduation theses of undergraduate, master's and doctoral students, assigning undergraduate students on a project basis within the scope of summer internships, and giving seminars with the participation of expert personnel in the R&D Center at universities are increased.

The most comprehensive technical competence casting widely used in the world Simulations of metal casting processes with the simulation program ANSYS is realized. If the valve casting process is not carried out correctly situations that will completely affect the subsequent processing, assembly, testing and use of the product in the line problems are experienced. Accurate casting is a very serious qualification. In our sector, all of our production processes have been reflected in the virtual environment with ANSYS. Every such as furnace temperature related to the product, alloy to be used, sprue locations of the material to be poured All technical details can be observed with this program. One of the 9 components of Industry 4.0 The "digital twin", that is, the simulation part, was thus realized.

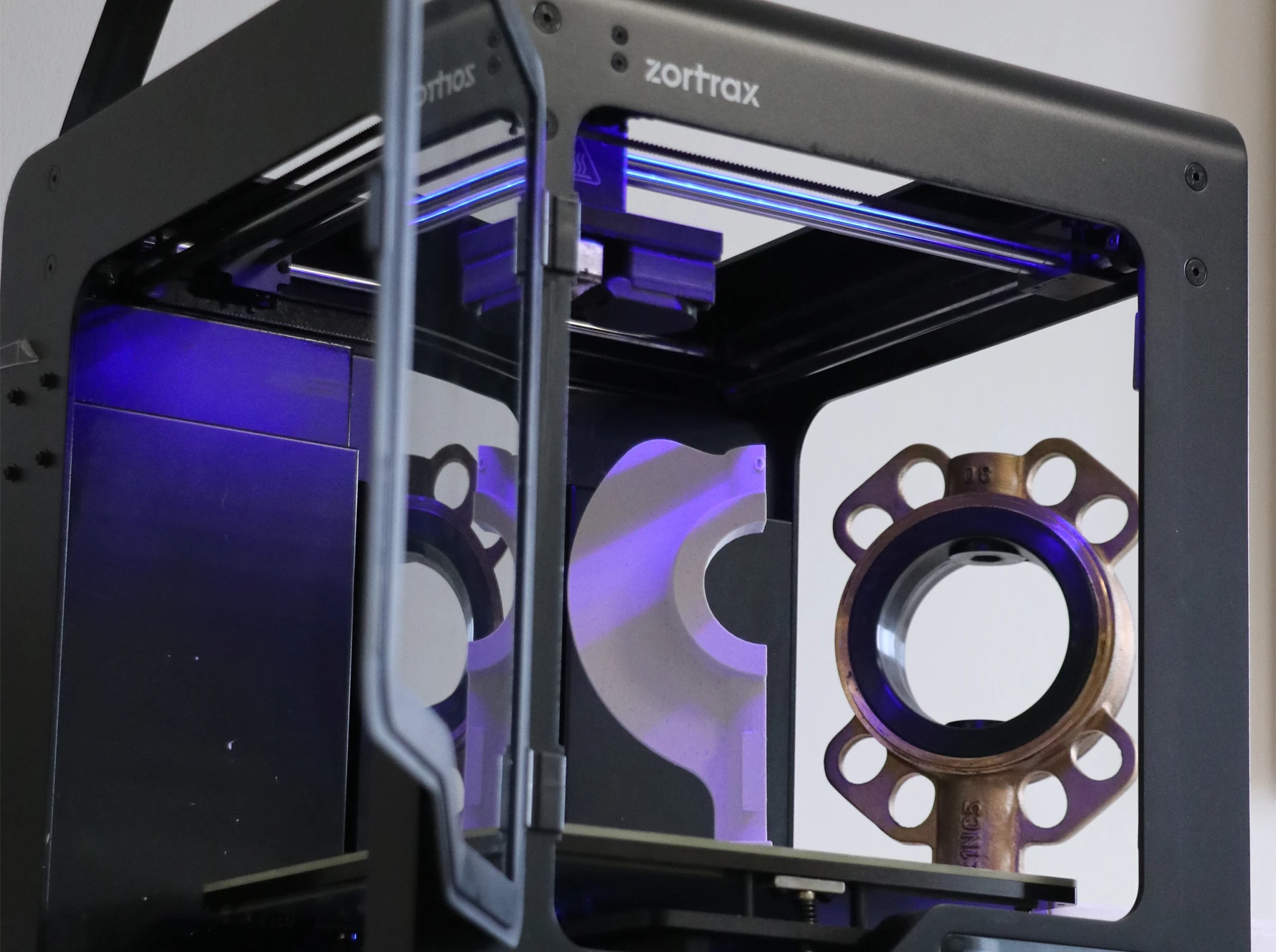

In our R&D Center, we leverage state-of-the-art 3D printers to execute all model and prototype production processes digitally. These cutting-edge printers allow us to quickly identify and optimize any issues in prototypes, enabling a seamless transition to mass production with the most efficient design.

This approach offers significant time and workforce savings, while simultaneously accelerating product development and industrialization processes. The ability to rapidly prototype and validate designs with 3D printing enables higher efficiency with fewer resources, making it possible to stay ahead of future industrial production trends.