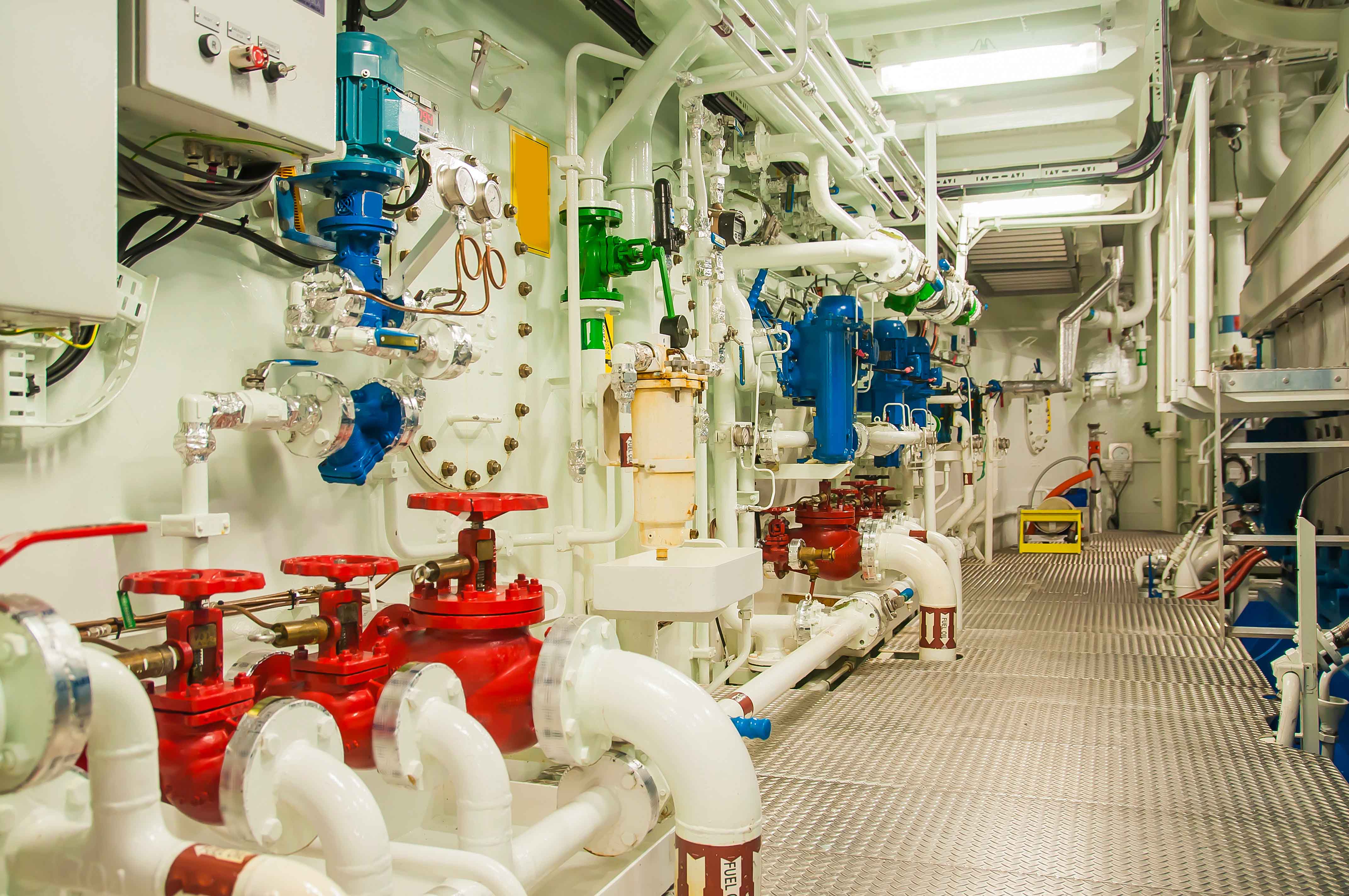

Marine valves are special valves used in the maritime and ship industry. They are used to control, direct or stop the flow of liquid, gas or steam in pipe systems on ships, and are critical to ensuring the safe and efficient operation of the ship.

They can be manufactured from a variety of materials and are designed to withstand marine conditions.

Some important factors taken into consideration in the design and manufacture of marine valves are:

• Corrosion Resistance: Materials that are resistant to marine conditions such as salt water and humidity are used.

• Durability: Strong structures are required for long-term use and high-pressure environments.

• Ease of Maintenance: Maintenance should be easy and parts that need to be replaced should be replaced quickly.

• Ballast Systems: Taking and discharging water into the ship to ensure the balance and stability of the ship.

• Cooling Systems: Controlling seawater flow to cool engines and other equipment

• Cooling Systems: Controlling seawater flow to cool engines and other equipment

• Fire Extinguishing Systems: Distribution of water to various areas within the ship for fire fighting

• Fuel Systems: Storage, transportation and delivery of fuel to engines

• Wastewater Management: Collection, transport and discharge of wastewater from the ship

• Hydraulic Systems: Operation of deck equipment and other hydraulic systems.

• Compressed Air Systems: Control of air flow for equipment and systems operating using compressed air.

The defense industry is a strategic field where quality, reliability, and advanced engineering standards converge. At Dikkan Valve, we act with full awareness of this responsibility, designing specialized valve solutions for military projects and serving as a reliable partner in the industry with our R&D and production capabilities.

· Naval vessels and submarines

· Fuel and water distribution systems

· Onboard fire suppression systems

· Bilge and ballast control systems

· Hydraulic and pneumatic circuits in armored land vehicles

· Cooling lines in mission-critical equipment

· Military infrastructure and support facilities

Compliant with VG norms, as well as MIL-SPEC and NATO standards, our valves are confidently used in both national and international military projects.

The water, wastewater, and seawater sectors are fundamental to global sustainability and public health. With the growing demand for clean water, the need for efficient wastewater treatment, and the increasing importance of seawater desalination, these industries are at the forefront of addressing some of the world’s most pressing challenges. As populations grow and urbanization expands, innovative solutions are crucial to ensuring the availability, quality, and management of water resources. These sectors play a vital role in preserving water supplies, protecting the environment, and ensuring a cleaner, healthier future for all.

We are experts in water and wastewater applications, offering an extensive range of industrial valves designed to meet the needs of these critical sectors. With a commitment to innovation and reliability, we provide tailored solutions for clients around the world, helping to advance water and wastewater infrastructure in many countries. Additionally, our specialized expertise extends to the growing desalination sector, where we deliver custom-made solutions to support the development of sustainable seawater treatment systems.

Oil drilling and degassing activities face various problems including extremely high temperatures, salt water, impurity, vibrations, explosion risk and high levels of mechanical stress, and the tools used in oil drilling and degassing activities are adversely affected by these problems, which occur frequently. Therefore, Dikkan Group manufactures valves that are suitable for use both on the surface and underground in order to ensure the safe movement of uids, mainly in the oil pipelines and gas lines.

Dikkan provides its customers with high-pressure resistant, durable, high quality valves that are equipped with high quality safety equipment and suitable for each and every step of drilling, degassing from the main source to transmission, renery, storage and distribution of these products.

Our main focus is to always improve in order to meet the requirements of energy industry. We develop new and above-the-standards solutions for our customers to meet the expectations in the sector.

Reliability and performance are key features in critical and combined powerplants. We are happy to meet our customers' expectations conforming to the international standards thanks to our cutting-edge-technology, quality and durable products with minimum malfunction time and highly efficient fluid control.

Furthermore, we are proud to provide our customers with efficient, quality and durable solutions thanks to our large scale manufacturing activities that are fitting each powerplant's (see below) requirements, safe and highly resistant to pressure and heat.

Taking into consideration the dynamics of the mining industry, we offer various, safe and reliable solutions. We guarantee high level of performance despite the extraneous materials in the lines, conformity to the international quality standards, highly safe equipment for our products while meeting the expectations of mining industry.

Having regard to the requirements of iron-steel industry, our portfolio is composed of durable, low maintenance, high pressure and heat resistant and quality products.

Chemical industry hosts a wide range of products with many different production processes. While conforming to the international standards, we have diligently created a product range in order to meet our customers' needs with safe, leakproof products that are not only resistant to high temperature and high pressure, but also ensure safe flow of dangerous and risky chemical fluids.

We present quality, high pressure, heat resistant and low-maintenance products, which guarantee sustainable performance, for the safe fluid control

We would like to contribute to the efforts for sustainable and profitable success in the rapidly growing pulp and paper industry, and for this purpose, we exert our efforts in managing efficient, reliable, durable and environmentally smarter processes. We provide suitable solutions for the paper industry with high pressure resistant, durable, quality and low maintenance products.